Do you have a project with which we can help you?

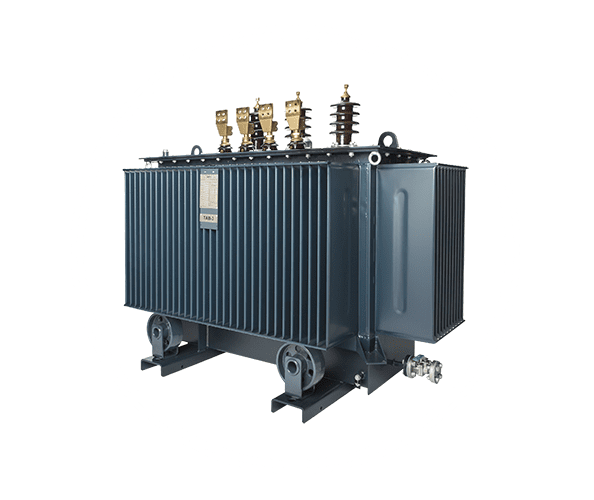

Oil Distribution Transformers

Our liquid immersed transformers for Europe are manufactured according to European Regulation Nº548 / 2014 with low losses (ecodesign), thus offering our customers high energy efficiency transformers.

Our Engineering Department designs and calculates our distribution transformers for both Europe and the rest of the world, which are subsequently manufactured using our technological means throughout the entire production process and final tests. All materials used in the manufacture of transformers pass strict quality controls before thier use, to ensure the maximum reliability and safety of the final product.

Distribution transformers in dielectric liquids are approved by numerous Electric Companies throughout the world. Obtaining these approvals and certifications along the trajectory of IMEFY has implied significant investments in technological equipment, at all levels, in a significant way.

Productive capacity:

10.000

units/year

Technical specifications

| Voltage | from 6 kV to 72.5 kV |

| Power | from 25 kVA to 5MVA |

According to national and international regulations in force.

Main applications

| Service sector (Hospitals, Hotels, Schools, Shopping Centers, etc.) |

| Infrastructures (Airports, Military Installations, Ports, etc.) |

| Industrial sector (Chemical Industries, Paper Factories, Silos, etc) |

| Agricultural sector (Agricultural Industry, Machinery, Lighting, etc.) |

| Elevation of energy (wind farms, photovoltaic, hydroelectric power stations, etc.) |

| Traction (Railways, Trams, etc.) |

| Maritime (Cruises, Offshore Platforms, etc) |

PERITUS OLTC TRANSFORMER

Peritus OLTC transformers (POTs) represent an advanced and effective solution to address the challenges faced by grid operators today, arising from changing consumption patterns and the increasing penetration of new forms of power generation, such as solar, wind and mini-hydro. Although they are not the only viable technical alternative, they stand out for their balance between cost, efficiency and regulatory compliance, provided that a detailed analysis of the grid has been carried out beforehand to identify critical points.

Numerous studies, pilot projects and real experiences show that, in most cases, POTs are the most sustainable and profitable option for stabilising the grid, adapting to growing demand, managing energy storage or facilitating electromobility, all within the framework of smart grids. For this reason, Imefy is committed to this technology as part of its commitment to a more efficient, resilient and environmentally friendly energy model.

SOIT TRANSFORMERS

DIELECTRIC LIQUID IMMERSED TRANSFORMERS FOR SOLAR FARMS

Normally the windings connected to the inverter circuit are not grounded. The grounded electrostatic shield placed between the primary and secondary windings is placed to prevent capacitive coupling of these windings.

The main advantage of this screen is to minimise the possible transfer of high frequency disturbances (harmonics, pulses, surges occurring in the inverter) from the primary winding (B.T.) to the secondary winding (A.T.) and into the power grid.

The other advantage of the electrostatic screen is to reduce the transfer of high voltage transient overvoltages to the primary winding(s) (B.V.) and the inverter connected to this primary winding. Without the electrostatic screen a high percentage of high voltage transients in the secondary winding (A.T.) could be transferred to the primary winding (B.T.) of the transformer.

In addition, the electrostatic screen acts as an additional filter dU/dt. The electrostatic screen can be made of either aluminium or copper, and when fitted to transformers it must be grounded at only one point. At the customer’s request an insulator can be fitted to the cover with the screen connected internally to earth through this insulator, rather than internally.