Do you have a project with which we can help you?

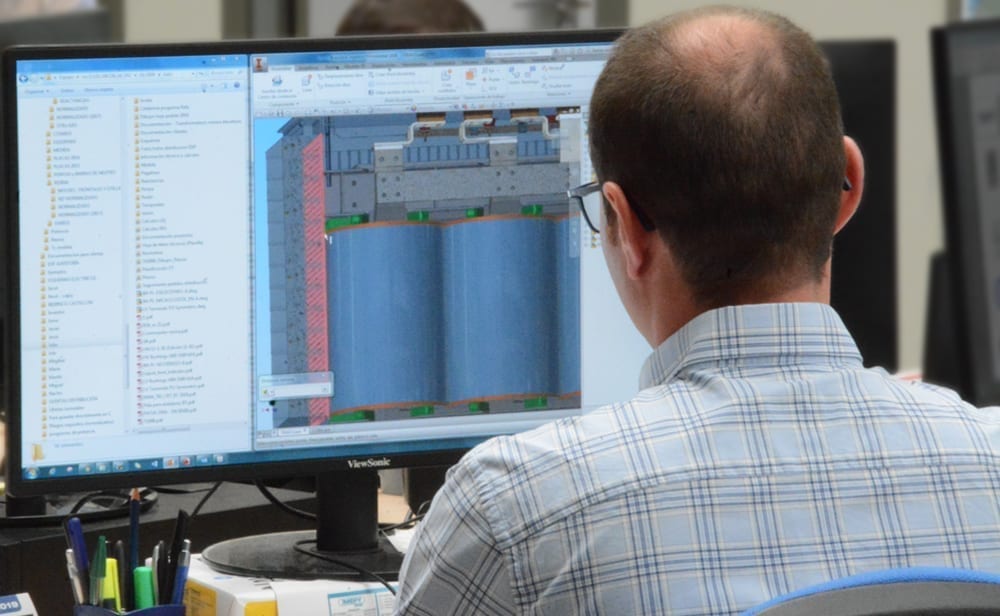

ENGINEERING

Engineering Area of IMEFY has as its main scope the CALCULATION AND DEVELOPMENT of the different projects which will be manufactured. It is also responsible for elaboration of the TECHNICAL BIDS, and serves as technical support to other areas.

This Area has the necessary human resources, as graduates, high degree engineers and assistants, all of them having extensive experience in the calculation of electrical and mechanical projects, especially in the field of different types of transformers that IMEFY designs and manufactures.

Our engineers are continuously updated of the latest developments and continuing advances in the field of transformers through specialized courses, active participation in technical forums, both national and international, as well as membership of Technical Committees, participating in the drafting of national and international standards, such as the AEN / CTN 207 / SC 14 AENOR or IEC (International Electrotechnical Commission) committee 14.

The Area of Engineering of IMEFY has also the collaboration and support of a high level CONSULTANTS with an experience of over 40 years in the design and manufacture of transformers of all types and complexity (oven, traction substation, generation etc.)

Relativo a los MEDIOS TÉCNICOS, contamos con los más modernos medios a nivel de equipos informáticos, software para diseño mecánico y eléctrico de empresas punteras en el sector del diseño y también con software para el cálculo y diseño de transformadores de desarrollo propio basado en la experiencia de nuestro personal y staff técnico junto con la experiencia acumulada durante más de 40 años en la fabricación de transformadores.

Los principales medios técnicos con los que contamos son:

- Programa de cálculo de transformadores de potencia, desarrollado por IMEFY.

- Programa Protomagnet: Elaboración de curvas de magnetización chapa magnética desarrollado por IMEFY

- Software de simulación elementos finitos para:

- Cálculo electromagnético transformadores.

- Pérdidas.

- Calentamiento.

- Esfuerzos mecánicos en cortocircuito.

- Software de simulación elementos finitos para:

- Cálculos de campo eléctrico en transformadores.

- Programa de diseño en 2D cad

- Software de diseño 3D cad, incluyendo:

- Módulo de simulación elementos finitos para el cálculo mecánico.

- Programa de cálculo transformadores y programa de elementos finitos de Ingeniero consultor.

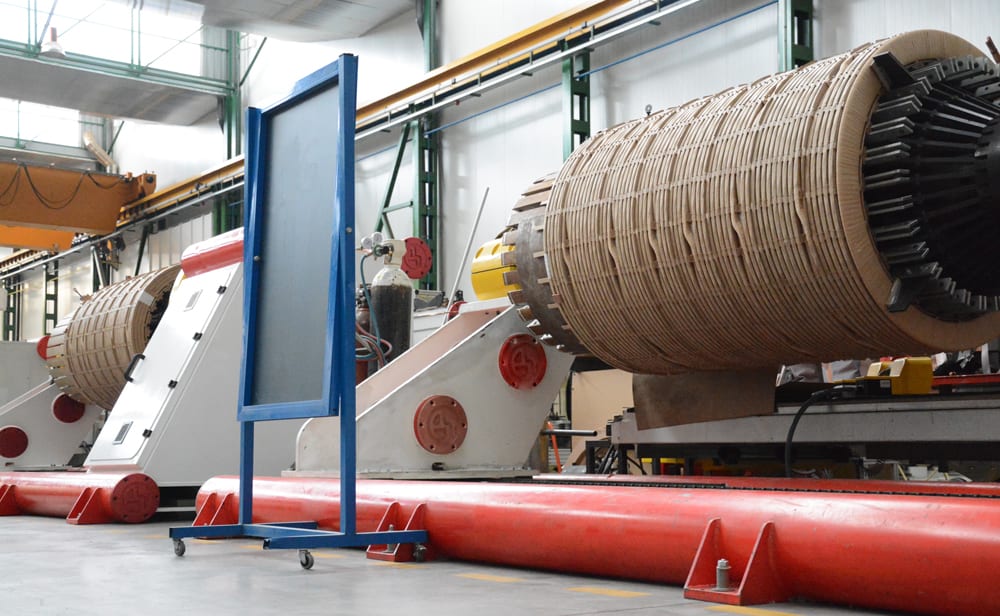

PRODUCTION

With three manufacture sections fully defined as Liquid immersed distribution transformers (9,000 m2), Cast resin Transformers (6,000 m2) and Power Transformers (4,500 m2), we are able to offer our customers a full range of transformers covering any need in the shortest possible time.

These three production lines, fully autonomous, are supplied by a common step prior to them, where it is manufactured the magnetic core of transformers (Cut of Magnetic Steel with 3,000 m2).

PRODUCTIVE MEANS

Staff

IMEFY counts on a staff of direct workers highly qualified and with great experience, easing a polyvalent, dynamic and resolutive grate.

Technology

Equipment properly maintained, by the drawing up of optimized, preventive and predictive plans of maintenance and specifically designed for each function in each production section, and constantly evolving to adapt to the technological innovations required by the development of our transformers.

Among them, we include:

Corte de chapa

3 GEORG cutting machines of magnetic steel of high efficiency and with a cutting capacity of more than 600 mm wide. Step Lap cutting method, and automatic stacking.

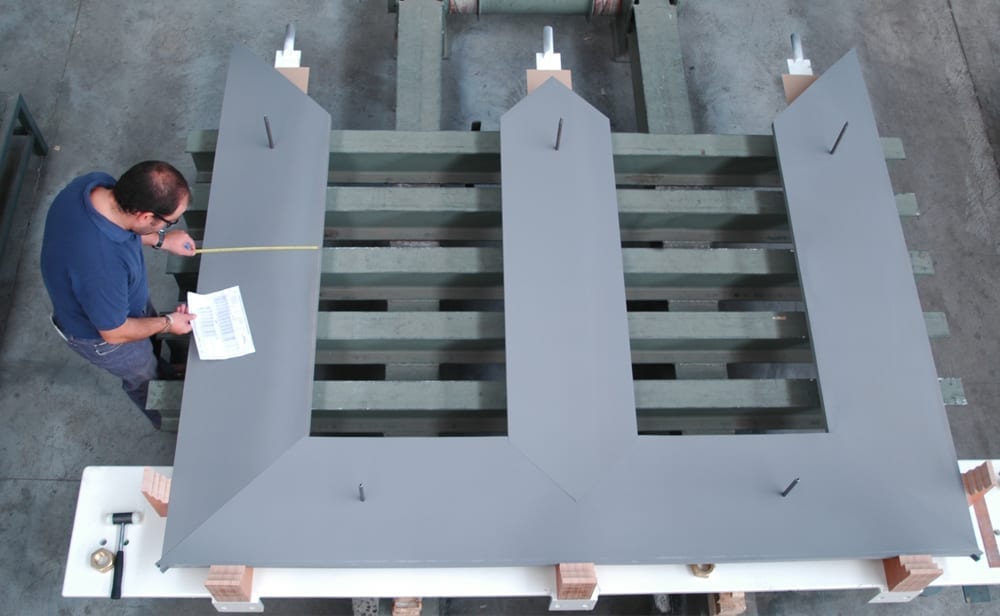

Assembling tools of magnetic core

Assembling tools of the magnetic core for any type of transformer, which are adaptable in dimensions and guided based by of bars high precision.

Winding

Machines specially designed for any type of winding, and all of them with special extensible tools, adaptable in inner diameter of winding according to the technical specification.

These machines are subjected to a strict study to ensure their optimum working at all the levels: efficiency, reliability and safety.

These machines have been developed together with leading manufacturers and some of them have been entirely developed by our staff.

Treatment of windings and complete phases

Depending of the type of transformer and winding, it is necessary to make a thermic treatment with compression phases, first on each winding, and then on the complete active part of transformer.

In some cases, as in cast resin transformers, the type of transformer requires these type of means (vacuum autoclave, cured ovens, etc..) in order to achieve the proper insulating means of transformer.

In this way, we have electric convection drying furnaces of air with renovation systems, under vacuum encapsulated autoclave at high temperature, machine for vertical pre-compression of windings and complete phases of big size, and finally, with drying system by means of vapor under vacuum of kerosene (Vapor Phase) of high efficiency which is suitable to dry active parts of transformers of big power and voltage.

Treatment of dielectric liquids

To ensure the better possible conditions of transformer in service it is indispensable to check the process of filling and do a correct treatment of the insulation means of transformer.

To do this, IMEFY has vacuum hood and autoclave, which allow us to do the filling process of transformer under vacuum, as well as equipment of dielectric oil treatment with possibility to control the quantity of removed water.

Control of production

Our Quality System ensures a strict control during each phase of production, which together with the experience of the different areas Responsible and workers, allows us to achieve a level of. inner rejections very reduced. We do controls during the intermediate phases of production in order to reduce the necessity to make reworks on our products.

All the transformers manufactured by IMEFY must pass all the routine tests of the standards in force. If any transformer does not pass these tests it is subjected to a rework or even it could be rejected.

Thanks to this rigorous control in every manufactured transformer, and especially in the prototypes of any new design, we can guarantee that all our transformers have passed these tests.

QUALITY

IMEFY as a company dedicated to manufacture products within electrical sector, has to live up to the requirements which such a strategic sector requires. So, besides having the required levels of quality (UNE-EN-ISO 9001) and Environmental Management System (UNE-EN-ISO 14001) for over 15 years, IMEFY considers as a priority the Quality Control Plans, which allow us to make and test everything that is designed and manufactured.

To do this, IMEFY dedicates the personal resources, with a highly qualified staff, as well as technical and financial resources, all of them necessary to carry out standard and voluntary operational controls.

Download our Environmental Performance Communication

LABORATORIES

OIT Laboratory (Liquid Immersed distribution transformers)

The equipment of H.V. Laboratory allows us to perform the tests and check the results in accordance with the actual applicable standards (UNE-EN/IEC 60076-1, ANSI C57.12.00). The following routine tests are performed in all of the transformers:

- Measurement of winding resistance.

- Measurement of voltage ratio and check of phase displacement.

- Measurement of no-load loss and current at 100% of rated voltage.

- Measurement of short-circuit impedance and load loss.

- Dielectric routine tests:

- Applied voltage test.

- Inducted voltage withstand test.

- Check of the ratio and polarity of built-in current transformers.

- Dimensional control.

On request and in accordance with the customer, IMEFY performs the following TYPE and/or SPECIAL tests:

- Measurement of zero-sequence impedance.

- Measurement of no load current harmonics.

- Full wave lightning impulse tests.

- Chopped wave lightning impulse test.

- Switching impulse test.

- Temperature-rise test

- Windings hot spot temperature-rise measurements

- Determination of sound level

- Measurement of capacitances windings-to-earth and between windings

- Measurement of dissipation factor of the insulation system capacitances

- Measurement of insulation resistance between each winding to earth and between windings

- Measurement of power taken by the fan and liquid pump motors

- Measurement of frequency response (FRA)

- RVM, recovery voltage measurement test

- Measurement of no-load loss and current at 110% of rated voltage

- Short-circuit withstand test (performed in independent Laboratory)

- Vacuum deflection test

- Pressure deflection test

- Measurement of dissolved gasses in dielectric liquid

- Determination of weight with transformer arranged for transport

- Check of external coating

- Check and applied voltage dielectric tests in accessories / protections.

- Dielectric test on dielectric liquid

- Other tests for transformers may be defined in the specific documents for specialized transformers.

CRT Laboratory (Cast resin distribution transformers)

The equipment of H.V. Laboratory allows us to perform the tests and check the results in accordance with the actual applicable standards (UNE-EN/IEC 60076-11, ANSI C57.12.01). The following routine tests are performed in all of the transformers:

- Measurement of winding resistance.

- Measurement of voltage ratio and check of phase displacement.

- Measurement of no-load loss and current at 100% of rated voltage.

- Measurement of short-circuit impedance and load losses.

- Measurement of partial discharges.

- Dimensional Control.

- Dielectric routine tests:

- Applied voltage test.

- Inducted voltage withstand test.

On request and in accordance with the customer, IMEFY performs the following TYPE and/or SPECIAL tests:

- Measurement of zero-sequence impedance.

- Measurement of no load current harmonics.

- Full wave lightning impulse tests

- Temperature-rise test

- Determination of sound level

- Measurement of insulation resistance between each winding to earth and between windings

- Check of external coating of metallic parts.

- Short-circuit withstand test (performed in independent Laboratory)

PT Laboratory (Power transformers)

The equipment of H.V. Laboratory allows us to perform the tests and check the results in accordance with the actual applicable standards (UNE-EN/IEC 60076, ANSI C57.12.00). The following routine tests are performed in all of the transformers:

- Measurement of winding resistance.

- Measurement of voltage ratio and check of phase displacement.

- Measurement of no-load loss and current at 100% of rated voltage.

- Measurement of short-circuit impedance and load loss.

- Dielectric routine tests:

- Applied voltage test.

- Inducted voltage withstand test with Partial Discharge measurement according to transformer characteristics and the standard in force.

- Test on on-load tap-changers.

- Check of the ratio and polarity of built-in current transformers.

- Check of core, frames and tank insulation.

- Dimensional control

- Additional routine tests for transformers with Um >72,5 kV:

- Measurement of capacitances windings-to-earth and between windings.

- Measurement of insulation resistance between each winding to earth and between windings.

- Measurement of dissipation factor of the insulation system capacitances.

- Measurement of dissolved gasses in dielectric liquid.

- Full wave lightning impulse tests.

- Measurement of no-load loss and current at 110% of rated voltage.

On request and in accordance with the customer, IMEFY performs the following TYPE and/or SPECIAL tests:

- Measurement of zero-sequence impedance.

- Measurement of no load current harmonics.

- Full wave lightning impulse tests for transformers with Um ≤ 72,5 Kv

- Chopped wave lightning impulse test.

- Switching impulse test.

- Temperature-rise test

- Windings hot spot temperature-rise measurements

- Determination of transient voltage transfer characteristics

- Determination of sound level

- Measurement of capacitances windings-to-earth and between windings

- Measurement of dissipation factor of the insulation system capacitances

- Measurement of insulation resistance between each winding to earth and between windings

- Measurement of power taken by the fan and liquid pump motors

- Measurement of frequency response (FRA)

- RVM, recovery voltage measurement test

- Measurement of no-load loss and current at 110% of rated voltage for transformers with Um ≤ 72,5 KV

- Short-circuit withstand test (performed in independent Laboratory)

- Vacuum deflection test

- Pressure deflection test

- Measurement of dissolved gasses in dielectric liquid

- Determination of weight with transformer arranged for transport

- Check of external coating

- Check and applied voltage dielectric tests in accessories / protections and their connections.

- Dielectric test on dielectric liquid

- Other special tests for transformers may be defined in the specific documents.

Raw Material Laboratory

The raw materials Laboratory is highly equipped to perform the following tests:

- Magnetic Steel:

- Specific losses

- Dimensional control

- Conductors:

- Dielectric strength control

- Adherence and flexibility control

- Dimensional control

- Corrosion Protection:

- Adherence control

- Thickness control

- Inlay test

- Persoz Hardenss test

- Specular brightness test

- Direct impact test

- Bending test

- Salded fog test

- Traction adherence test

- Epoxidic elements:

- Inducted voltage withstand test

- Determination of the creepage line

- Thermal shock

- Test of gelling temperature of epoxy resin

- Dielectric Liquids:

- Water content

- Interfacial stress

- Dielectric breakdown voltage

- Dielectric losses (tgd)

- Density test

- Neutralization number

- Chromatographic analysis of gasses

- Other tests:

- Verification of auxiliary circuits

- Dielectric strength of solid insulators

- Ageing of materials

- Thermic programming of temperature control units

All these tests allow IMEFY to ensure the high quality of transformers. IMEFY reserves the right to make any changes that it considers necessary due to the best technological level or changing standards. For more information IMEFY has instruction manuals for installation and maintenance.

RESEARCH, DEVELOPMENT AND INNOVATION

IMEFY, virtually since its origin, has considered as one of the most important aspects of its Corporate Policy, Research and Development as a cornerstone, consequence of strategic sector and scope of the products IMEFY designs and manufactures. Years later, already in the XXI century, IMEFY introduced Innovation in its Corporate Policy, fulfilling a defined strategic plan and developed years before. The Policy focused on these aspects has involved the development as a company in the scope of:

- Technological advances of products.

- Direct involvement in decisions about standards.

- Internal development of the Company both in global growth (personal, machinery, equipment, area, etc …) as adding new products.

- Competitiveness, being present not only in the domestic market but in several international markets.

- Internal and external recognized prestige.

There are many different projects developed during these years. Briefly summarizing some of them we have:

- Incorporation of requirements C2, E2, F1 in encapsulated transformers. In his time IMEFY was pioneer.

- Development of elastic tanks in distribution transformers. In his time IMEFY was pioneer.

- Internal development of software for design of specific applications in the development of distribution transformers and power transformers.

- Development of sheet metal cutting systems for transformers cores.

Currently we are developing new projects, such as:

- Development of distribution transformers with amorphous cores and low losses.

- Development of cast resin transformers with materials having its application to marine mills.

- Development of power transformers with vegetable oils.

- Development of computerized testing laboratories.

- Development of new products in our industry (processing centers, etc …)

- Development of power transformers with aluminium.

To summarize, the Strategic Policy of the Company considers the Research, Development and Innovation as one of the cornerstones of future development, focusing it planning in market trends.

To do this, IMEFY dedicates the Human and Financial Resources to enhance the strategic plan for R+D+I, in planning, development, monitoring and continuous evolution.